Can 3D Printing of Alternative Proteins Take Off?

Table of contents

Regular readers will be familiar with Gartner’s Hype Cycle for emerging technologies, which graphically represents the ups and downs that most new technologies undergo, as they move from the “that’s super cool” stage to “what’s it good for” stage to “here’s how we can actually make money” stage. We often refer to the Hype Cycle in articles about 3D printing – a technology with great potential but mixed results so far. 3D printing stocks, for example, continue to struggle, while some companies are finding success in on-demand manufacturing. Metal 3D printing, in particular, is showing signs that it can compete with traditional manufacturing. On the other hand, there are some applications that seem heavy on the hype, like 3D food printing. We’ve recently come across an even more niche 3D printing food category that is riding an even trendier market: alternative proteins.

The switch from animal products to foods that mimic meat and dairy has snowballed in the last few years, driven by concerns over climate change, human health, and animal welfare. That has led companies to cook up all sorts of alternative proteins, from growing single-cell proteins that feed on methane to fermenting dairy proteins with genetically modified yeast to producing real burgers or seafood from animal cells in a lab. Now a small handful of companies are turning to 3D printing for making alternative proteins.

3D Printing Plant-based Alternative Proteins

It hopes to roll out its semi-industrial 3D printers by 2020, marketing the machines to supermarkets for consumers and meat distributors for restaurants.

Update 02/16/2021: Redefine Meat has raised $29 million in Series A funding to finance the rollout of its 3D-printed meat substitute. This brings the company’s total funding to $35 million to date.

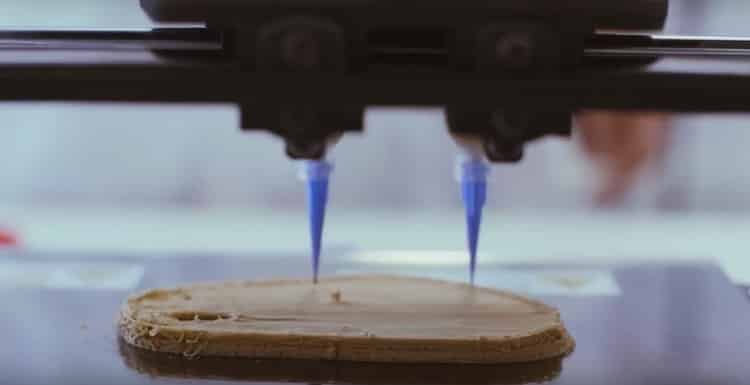

The printer extrudes a paste onto a printing plate using a design that Scionti created on CAD software. The price point is currently about $3 per 100 grams, which works out to about $13.50 per pound.

3D Printing Animal-Based Alternative Proteins

More established alternative protein companies are also turning to 3D printing technology. Yet another Israeli company, Aleph Farms, recently made headlines for 3D printing meat in space. Founded in 2017, Aleph has raised $14.4 million, including a $12 million Series A in May that involved food giant Cargill. The startup is part of the growing cohort of companies growing real meat from animal cells, and it expects to have the first lab-grown steak in limited markets in just a couple of years. The company went even further this month by announcing it had 3D printed a small piece of cow muscle tissue on the International Space Station in collaboration with a company called 3D Bioprinting Solutions.

Space.com reported that the experiment involved using a bioprinter that is equipped with a magnetic force that aggregates the cells into one small-scaled tissue that one could conceivably call meat. We’ll stick with Tang for now.

Update 07/07/2021: Aleph Farms has raised $105 million in Series B funding to bring its cultured, slaughter-free meat to market next year. This brings the company’s total funding to $236.4 million to date.

We first introduced you to Irish startup Perfect Day almost two years ago. It has raised about $61.5 million to date for creating dairy products without cows by genetically modifying yeast cells to produce casein and whey, the main proteins in milk. The company uses a special 3D printer to insert parts of a cow’s modified DNA into specific locations in the yeast, which has been dubbed Buttercup. In 2018, the company signed a deal with Archer-Daniels-Midland (ADM) to bring its dairy-free proteins to the food industry this year. (ADM happens to be one of the holdings in our dividend growth investing portfolio.)

Conclusion

3D printing appears to be finally emerging from a niche technology to a mainstream manufacturing process in everything from rockets to dentistry. Its use in the development and process of making alternative proteins isn’t surprising, though it remains to be seen whether it will be a fringe technique or experience widespread use in the next few years. At least one analyst at Lux Research is bearish on the whole thing, concluding, “Given that 3D printing of plant-based meats is essentially a niche within a niche, we do not recommend that clients engage with this space.” One could also dismiss Aleph Farms and its space-based experiment as more gimmick than game-changer. And research into developing full-on DNA 3D printers is intriguing but also in its early stages, with at least one company called Cambrian Genomics meeting an early demise with its owner’s death at 31. At this point, best to order a 3D-printed pizza and sit this one out on the sidelines.

Sign up to our newsletter to get more of our great research delivered straight to your inbox!

Nanalyze Weekly includes useful insights written by our team of underpaid MBAs, research on new disruptive technology stocks flying under the radar, and summaries of our recent research. Always 100% free.